.:: Pneumatic Cannon ::.

Pneumatic Linear Accelerator

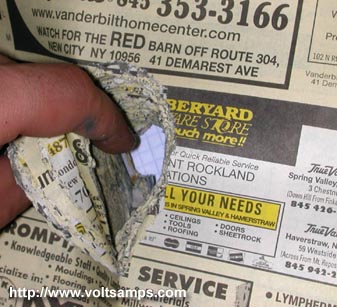

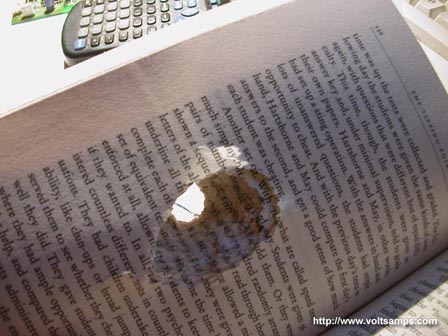

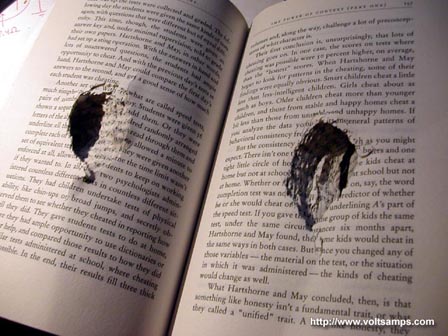

Various pneumatic cannon designs and the damage they can cause.

PNEUMATIC CANNON THEORY

Pneumatic cannons are like combustion potato cannons, however instead of combustion, they use compressed air.

When the valve opens, air rushes out from the pressure tank through the valve and finally reaches the projectile. The pressre then pushes the projectile umtil it exits the barrel.

There are different ways to design them, however there are three things that all cannons must have.

A pneumatic cannon must have a pressure tank, a high pressure valve and a barrel.

A pressure tank can be made of PVC, copper or steel tubing. WARNING: DO NOT USE DWV PVC COUPLERS!!! THEY WILL EXPLODE!!

In order to pressurize the cannon pressure tank, you will need to install a car tire valve somewhere on your cannon before the main valve.

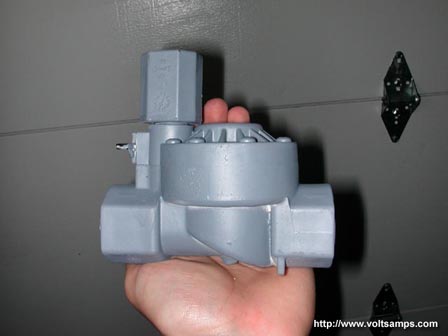

You can use sprinkler valves, or ball valves. However a sprinkler valve will produce a higher output. The faster the valve opens, the more power the cannon will put out.

1" sprinkler valve: max failing pressure 150 PSI. Suggested pressure 90 to 120 PSI. In order to trigger the valve, pressure from above the diaphragm needs to be released. You can use the solenoid that it came with, or you can use an external valve. With an external trigger however, you will need to drill and tap the top of the valve. Be sure to take the top off before drilling. Do not get plastic shavings into the valve system. This may cause the valve to not fully close, and you will not be able to pressurize the cannon.

1" ball valve: PSI dependings on model. Not recomended. Very slow "open-time"

CANNON DESIGNS (Thank you Peter Ubriaco, for the ideas)...

DAMAGE...